News

4 most common questions about sandblasting

In this article, Growell Vietnam will answer four most common questions about sandblasting and help you understanding deeply about this field.

1. What is sandblasting?

Sandblasting can be defined as one of the effective methods with which a surface can be shaped, stripped and smoothened and all foreign material is removed. It can be related to sandpaper for their similar effects. The material receives a completely rejuvenated look and a better finish. All nooks and corners get completely clean. This method involves air blasting whereby very small material pieces are shot at a very high pressure in order to etch or clean them.

Surfaces such as glass, wood, metal and brick can be sandblasted with ease. The typical material used for sandblasting has been sand but in recent times materials such as copper slag, steel grit, baking soda, glass beads, dry ice and walnut shells have also been used as media due to several health concerns. All these media can be ground in different degrees from fine to coarse materials. Level of productivity as well as cost of materials can be chosen as per your requirement.

2. What is the different between sandblasting and shot blasting?

Sandblasting

Sandblasting is defined by aggressively smoothing down a rough surface with the use of a strong diesel-propelled stream of sand. This technique has been used since the 1800s for a large variety of purposes by numerous industries such as construction – where there is a need to remove paint quickly and easily – or local council maintenance in cleaning concrete pavements.

The impact of sand blasting services can be altered by varying the type of sand, such as fine-grained silica sand or sturdy steel grit, which can be decided on a job-to-job basis. As sandblasting services can be dangerous to the health of the person who is operating the machine, seeking a professional engineer to perform the job is vital.

Shot blasting

Shot blasting is the process of propelling steel shot via compressed air to remove paint, rust or other surface imperfections from most metal structures. This restores metalwork as close to its original condition as possible, increasing its lifespan and aesthetic appeal.

While shot blasting is useful for construction and refurbishment, like sand blasting, shot blasting’s focus on treating metal makes it most suitable for industries regularly using metal structures. Examples of industries in which shot blasting is regularly used include: oil and gas, aerospace, automotive, and rail, along with domestic applications, such as garden furniture.

As shot blasting can be a dangerous technique, precision is a key consideration. That’s why, similarly to sand blasting, shot blasting is best performed by a trained professional. Most shot blasting services will also use a dust filtration system to reduce the risk of inhaling dust created by the procedure, in-keeping with EU regulations.

3. How much air pressure is needed for sandblasting?

Normally it starts with 5kg/cm2. Pressure is starting range for sand blasting of profile margin of SA 2.5, but here consider the hose pipe size and blasting nozzle size, the bigger the gauge of pipe you need more pressure while pressure itself isn’t the only factor, you need to know about CFM capacity of the Air compressor you use, the more CFM value the more delivery you receive.

Generally, people use 250 to 335CFM compressor with 6.5 to 7.5 kg pressure to get best result of blasting. Kindly note here, higher pressure means the more area in less time!

4. What kind of sand should I use for sandblasting?

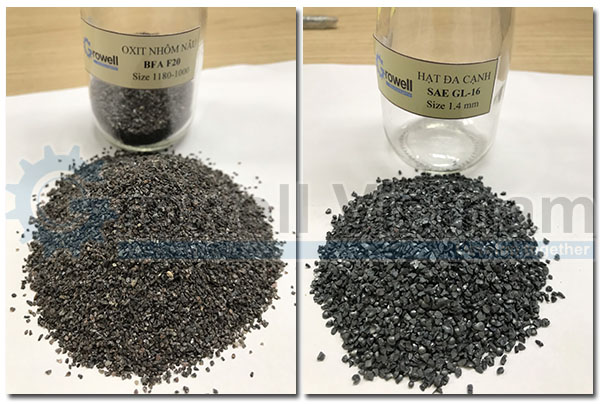

The sand that you need to use depends on the machine that you are using it with and the kind of sandblasting that you are about to do. Most of the time, Steel grit and aluminium oxide are used because it helps to remove the impurities and make the product smoother, thanks to it roughness and the kind of sharpness that it has with it. Fine sand is not a good idea to go with because it will not have the same kind of impact that you can find with rough sand

Before you decide to go for the sand, look at the type of machinery that you are using and decide. It will help you give a better knowledge about what kind of sand would work the best considering the kind of product you are creating as well. Another thing you need to consider is the size of the product. So, if it is a large material or product, larger grains might be in need

CONTACT US NOW TO GET MORE DETAILED CONSULTANCY ON SANDBLASTING

Reference articles:

Introducing about suction cabinet Growell VN

Introducing about blasting room

How to choose the right abrasive sand?