News

Spare part of Shot Blasting Machine

Spare part of shot blasting machine is very important and indispensable in shoting process. It is not easy to select the good spare part because it requires buyers to have technical knowledge. In this article, Growell VN will give you some informations about spare part of shot blasting machine.

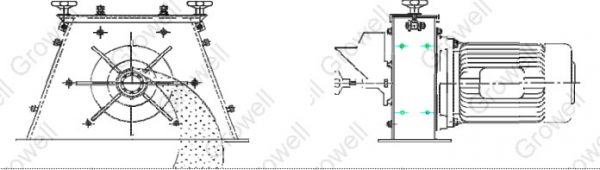

Rotor wheel

The rotor wheel is the most important part of shot blasting machine. When it is rotate by the motor, all blades move very fast and throw the accelerated shots on to the work pieces.

The blades, impeller of the rotor wheel are fixed to the shaft and rotate together with the shaft. The deflector is fixed to the chute is revolved by the impeller and is thrown out through the deflector outlet. The abrasive is accelerated by the blades and is thrown against the work pieces.

By this rotor wheel model use direct drive, it can save cost for maintenance for overhaul.

Blade

The blades tend to wear out most quickly out of all component parts of a shot blasting machine. They are turned at high speed. Therefore, before operation, be sure to check they are worn seriously of and blade fixing pin is getting loose. When the blades are worn minimum wall thickness is not less than 3mm, it cause to break suddenly during operation, and will cause the impact and vibration before it is required full attention and replace with new completed blades (8 pcs). Do not replace only one broken blade, the unbalance motion and vibration will take place. It must be changed at least two blades opposing each other at the same time.

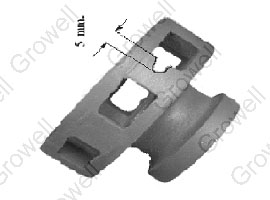

Deflector

Control cages are easy to wear quickly the shots projected from impeller (or distributor) come out from the deflector window in to the rotor blades. Check the worn condition especially when the rectangular abrasive outlet (deflector window) become larger than 15mm. Replace the new one. If the worn deflector is used as it is blasting effect decreases and the other parts will wear out quickly.

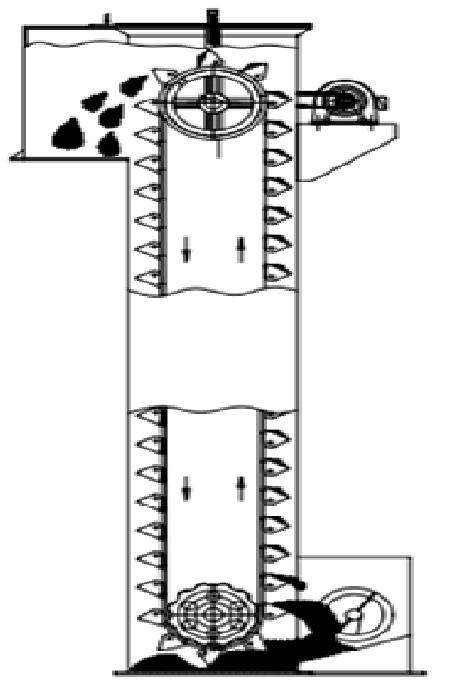

Bucket elevator

The bucket elevator is centrifugal with top torsion type for delivering the abrasive go up to the abrasive cleaner. The mid steel bucket, are fixed to the canvas bolt by means of bolt and nut. The top pay of the bucket elevator. There is the top pulley with the take up for adjusting the belt tension his case is integral with the abrasive cleaner separator.

To be inspect the bucket belt everyday before or after using. If the belt tension is adequate and leaning toward one side, carefully check. When the belt tends to stretch in the initial period after installation. Therefore gradually raise the belt tension device (take-up). When the belt tension device go up the highest position we have to cut the belt shorter approximately 10-20 cm at the belt connecting part.

Impeller

The distributor or impeller is located within the control. Cage and sends the shots through the deflector window by a fixed centrifugal force. Their circulation axles are fixed with left thread bolt. If any is own down to a services limit shown imagine or more, replace the new one.

Where can you buy shot blasting machine spare part?

Growell is a leading group in the field of manufacturing shot blasting machine and sand blasting machine with over 20 years of experience. All shot blasting machine spare parts are distributed directly by Growell Vietnam. In addition to the above spare part, Growell also distributes other spare part such as nozzles, liner plate, sand blasting gun, gloves, protective gear,…

CONTACT US RIGHT NOW TO GET MORE DETAILED INFORMATION ABOUT SPARE PART OF SHOT BLASTING MACHINE