News

Process description of Rotary hanger shot blasting machine

Rotary hanger shot blasting machine is specially designed for the blast cleaning of various components such as medium or small castings, forging parts, automobile parts, alloys wheels, gear parts, ect. The design incorporates a centrifugal turbine, turned table mechanism, rotating hook mechanism, screw conveyor (horizontal and vertical), bucket elevator, abrasives separator, dust collector and control panel. The surface of the work piece is thus evenly blasted from all angles and even difficult to reach areas are optimally treated. Operation and process control can be set by the operator to allow for a broad range of jobs and preparations. Media is continuously recycled and recovered, which separates round blast media from broken media, debris and dust.

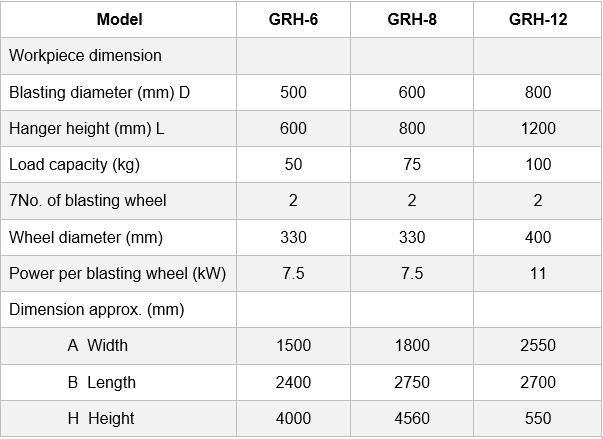

Specification of Rotary hanger shot blasting machine

Process description of Rotary hanger shot blasting machine

The components to be cleaned are to be hung on the hook of a hanger’s attached to the turntable on the tiop of cabinet, and are transport into the blasting chamber with the slow rotation of turntable. This turntable mechanism are divided into 2 segments and each individual hanger hava a load capacity of 75 kg for maximum components size of diameter 600 mm and height 800 mm. One segment of the turntable hanger is expoed to the outside of the cabinet for continues preparation of loading/unloading of components to be cleaned.

Two blasting wheel are mounted at the most suitable inner segment position to get the maximum blast cleaning efficiency. The components will be exposed to the cleaing action of the abrasive throw by the centrifugal wheel unit, and the contaminants removed from the work, drop to the bottom of the screw conveyor. The abrasive and contaminants are passed into the recycling system consisting of a bucket elevator, abrasive sieve separator, storage hopper and feed pipes. The cleaned and good reusable abrasive gravitates into the storage hopper ready for the re-feeding to the centrifugal wheel unit.

CONTACT US NOW TO GET MORE DETAILED CONSULTANCY ON ROTARY HANGER SHOT BLASTING MACHINE

Reference articles:

Introducing about suction cabinet Growell VN

Introducing about blasting room

How to choose the right abrasive sand?