News

All about Steel Shot Blasting

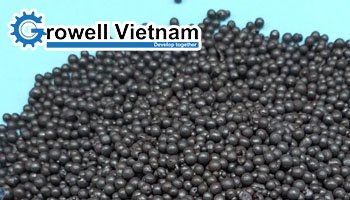

Steel shot blasting is exceptionally durable, due to its low friability (a abrasive media can have same hardness but different friability similar to that of durability). The impact of blasting actually tempers the steel shots so that its hardness increases over time, allowing the blasting media to give consistency, repeating the same performance for thousands of cycles. It has extremely low breakdown rate, even no dust is produced. Due to high-impact energy and fast cleaning rates, steel shot is used for heavy scouring and to produce very bright finishing surface in sand blasting/shot blasting machine. These steel shot blasting reduce maintenance cost of blasting machine many times.

Steel Shot blasting function

- Removal of surface contaminants, giving a complete clean surface that helps in inspection for process defects.

- Surface preparation: Provides a surface profile (etch, smoothen, matte finish) preparatory to further processing like coating, painting, etc.

- Cleaning of metal, glass, wooden, etc. surfaces.

- Descaling

- Debugging

Advantages of Steel Shot

- It provides excellent result on the metal Surface.

- High Durability.

- Cost-effective & recycle ability is strong.

- Used in both wheel blast systems and air powered blasting machines.

- Remove surface contamination and provide a completely clean, smooth surface.

Features of steel shot

- Steel shots have long working life

- Steel shots have uniform size

- Steel shots provide good service

Steel Shot abrasive media is available in all standard sizes for use in wheel blasting and pressure blasting systems for stripping, cleaning, deburring, finishing, smoothening and metal surface-improvement.

Properties of steel shot blasting

Mostly steel abrasives are manufactured from high-carbon steel composition, the best compromise between mechanical and chemical properties, efficiency and durability. The most vital properties for steel abrasives are hardness, size and shape, toughness and cleanliness.

- Recyclability and environmental impact of steel abrasives

The recyclability of steel shots ranges between 1000 and 2000 cycles. Due to its high recyclability level, steel shots tend to generate less wastage when compared to other abrasive media.

- Hardness of steel shot abrasives

Steel shot is available at different hardness levels, ranging between 35 and 55 on the scale.

Contact us:

Growell Vietnam Co.,Ltd

Hotline: (+84) 90.172.1919

Email: growellvietnam@gmail.com