News

How much do you know about Shot blast machine?

Shot blasting is a process used for the treatment of surfaces with the assistance of high velocity steel abrasives. The shot blasting method aids inobtaining exceptional cleaning and preparation of the surfaces for the secondary finishing operations. Shot blast machine is commonly used for the purpose of thefollowing:

- For cleaning of metals like: iron, steel, forgings, non-cast parts and many more.

- For mechanical cleaning of: sheets, wire, rods, coils, etc.

- For shot peening to alter the mechanical properties such as forincreasing resistance to fatigue for springs, gears, etc.

- Preparation of surfaces for secondary operations like painting, coating, etc.

In general, the process ofshot blasting focuses on throwing the abrasiveparticles at a high speed of 65 to 110 m/second in a highly controlled way atthe material to be blasted and as a result removing the contaminates on thesurface with the help of the abrasive impact

Shot blast machine

For understanding which is the best option, one must gain complete knowledge about the concept of the process as well as the machines that are used for the shot blasting process.

Different parts of the Shot blast machine

The shot blast machine consists of six different parts:

- Blast Wheel

- Cabinet

- Work Handling Mechanism

- Elevator

- Separator

- Dust collector

To determine the role each part of the machine plays in the shot blasting process it is important to acquire the complete knowledge about the sandblasting process and machine. The following is a detailed description of the function of each part of the machine in the shot blasting process:

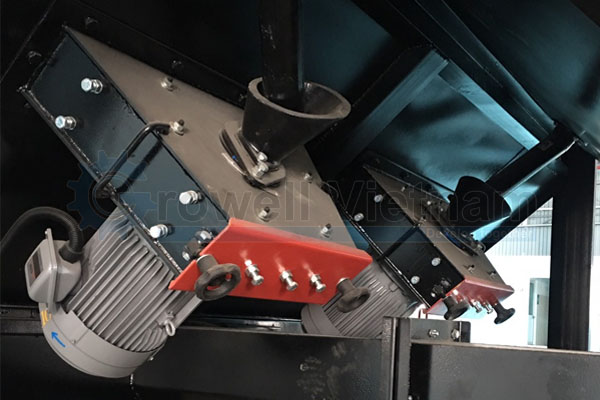

1. The Blast Wheel

The wheel is the focal part of every centrifugal shot blast machine. The wheels help the abrasive particles which are projected through the centrifugalforce from various types of turbine wheels. If the quality of the wheels is at an optimum level then the efficiency as well as the cleaning effect turns out to begreat.

2. The blasting cabinet

Just like the blast wheel, the blasting cabinet too is an important part of the shot blasting machine. As, the high speed of the abrasive particles have to betreated in a closed and vibration free cabinet. This helps in ensuring theirstrength as well as their durability, these cabinets are made with the assistanceof superior quality of the steel material.

3. The Work Handling Mechanism

Most of the systems within the machine exist for conveying the parts which depends on the type, size and the quality of the items that need to be treated. There are a variety of types and designs of the shot blast machines that are used for different working process like the Apron Type Shot Blasting Machine, Hanger Type Shot Blasting Machine, Roller Conveyor Shot Blasting Machine, Rotary Hanger Shot Blasting Machine.

4. The Elevator and Abrasive Recovery System

This part holds a special place in the machine and maintains a steady functioning of the machine by helping the machine to recover the used abrasives. The abrasives are recovered at the base of the cabinet with the help f a screw conveyor and are further delivered towards the base of the elevator, which then carries these abrasives to the separator for further action.

5. The Separator Section

The Separator plays an extremely important role in the abrasive blasting machine. This is the essential part that helps to clean all contaminants beforeabrasives enter into the blast wheel for reuse.

6. The Dust Collector

This is the final and the most important part of shot blasting machine. The dustcollector is a part that is used mainly for the purpose of filtration. Thisimportant part helps in retrieving the dust filled air from the separator andfrom the dusty air that gets trapped in the cabinet ventilation system andreleases clean air into the atmosphere for ensuring an environment that ispollution free.

Sandblasting is a difficult process and requires the use of professionall yequipped techniques and equipment to employ this process correctly. Toprovide you with this efficient system of blasting services with the ideal shot blast machine, Growell Vietnam a leading manufacture, supplier, and exporter brings to you a range of metal shots and machines. Its efficiency has become a highly acknowledge facet of this company in providing competitive services as well as machinery for the blasting and painting industries. A premium brand name in this industry with its niche variety of services provides accessories for protective coating industries as well

CONTACT US NOW TO GET MORE DETAILED CONSULTANCY ON HANGER TYPE SHOT BLASTING MACHINE

Reference articles:

Introducing about suction cabinet Growell VN

Introducing about blasting room

How to choose the right abrasive sand?