News

Shot blasting machine Spare part

Shot blasting machine Spare parts

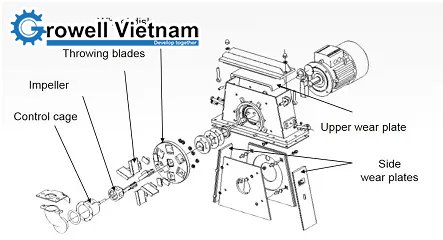

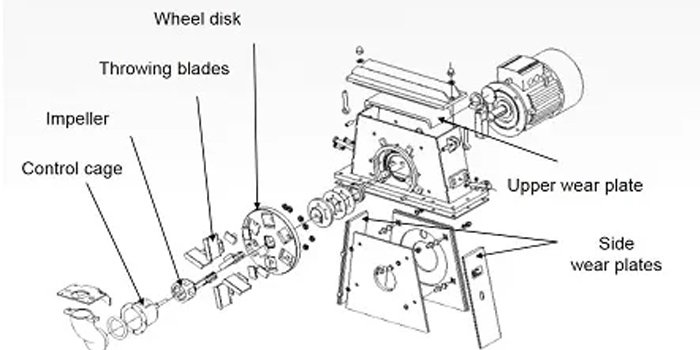

The blades, control cage, impellor, side and top liner plates in the blast wheels themselves, and the wear protection plates in the blast zone are the wear parts in your shot blast machine (in the area calculated to have the most impact from the abrasive when it is thrown from the wheel).

These components will experience wear each time the machine is used, thus they must be inspected frequently. When minimal material section parameters are achieved, wear components must be replaced. Thinning of parts and sections must be observed. Many worn components have options for tougher materials to increase service life and reduce downtime when replacement frequency is deemed to be too high.

In the case of wear plates in the blast chamber these are protecting the housing material of the blasting machine which would otherwise be destroyed. To protect your machine, these must be changed once a minimum thickness is determined. Due to the straightforward, hung fixing technique, Growell machines may be easily replaced when they break.

Replacing shot blasting machine spare parts

The way the abrasive is flung is influenced by the wheel spares, in particular the blades/vanes, impellors, and control cages. These worn parts need to receive special consideration. Changes in the blast pattern can cause abrasive to be thrown into wear-plate-unprotected portions of the machine, blast into wheel housings, and miss the parts that need to be treated. If this isn’t taken care of, the machine could suffer significant wear and damage that would be expensive to repair.

When replacing worn shot blasting machine spare parts, it’s crucial to follow the OEM’s guidelines (such as the replacement parts’ quality, proper dimensions and hardness, replacement processes, etc.). To guarantee the integrity and function of the blast wheel after repair, it is necessary in some instances to replace sets of parts rather than the individual wear sections. The manufacturer will always recommend these.