News

Shape, Hardness and Recycle rate of Glass beads

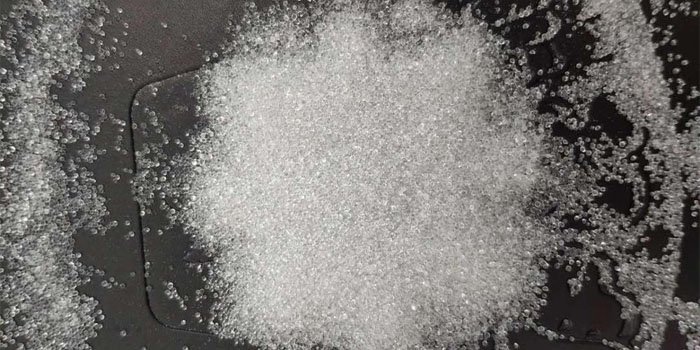

Glass beads is undoubtedly the most common and equipment-friendly of all media blasting abrasives. This is due in part to how adaptable glass beads are. They are a variety of sizes, shapes, and hardness levels and are a medium-hard abrasive. These qualities of glass beads influence their rate of recycling and make them valuable.

Taking Abrasive Hardness Readings

Abrasive hardness is often described for blasting abrasives using the Mohs Scale for Mineral Hardness, but it can also be determined using the Rockwell C Scale, HRC, or Vickers Scale. We at Growell Vietnam employ the Mohs Scale of Mineral Hardness since it is almost universally used to classify blasting abrasives for abrasive blasting cabinets.

The Mohs Scale for Mineral Hardness rates materials based on their hardness, with Diamond being the hardest mineral and Talc being the softest. The harder end of the range, Silicon Carbide, is located closer to Diamond, whereas soda abrasives are more similar to Talc.

The Mohs Scale gives glass beads a hardness rating of around 5.5 – 6, which places them right in the middle of the pack. Since most projects are neither too hard nor too soft, they can resist glass bead blasting.

Glass Beads Blasting: The Perfect Shape for an Abrasive

Another crucial element that is rarely highlighted is the grain’s form for blasting. Glass beads have a Mohs hardness of roughly 5.5, but their form gives them a significant advantage over other abrasive materials.

Recycle Rates by Type of Abrasive

The sharpest and harshest abrasives can also be fragile. While it’s crucial to use the appropriate abrasive for each application, a general rule is to use harsh abrasives against soft materials like glass, wood, and plastics. Metals like steel, aluminum, cast iron, and wood can all be cleaned with glass beads.

Real World Example: Abrasive blasting isn’t so different from sandpaper. Sandpaper that is pink or red in color and recommended for use on softer wood parts is frequently manufactured with garnet. Brown sandpaper is used for general sanding and grinding of softer steel parts and typically contains aluminum oxide. Black sandpaper is typically silicon carbide, which is extremely hard and sharp but short-lived.

Knowing what you are currently using as an abrasive will help you choose the best abrasive for your application. Here is a handy sheet for recycling rates:

- High Rates of Recycling: Ceramic Beads; Steel shot & Steel Grit, Stainless Steel Shot

- Medium Recycle Rates: Aluminum Oxide, Glass Beads, Plastic and Silicon Carbide

- Low Recycle Rates: Walnut, Garnet, Silica Sand, Soda,…

Contact us:

Growell Vietnam Co., Ltd

Hotline: (+84) 932 289 569

Email: growellvietnam@gmail.com