News

What abrasive media to use for your sandblasting project?

Abrasive media for sandblasting equipment is used for a wide variety of applications including sand blasting, tumble deburring, polishing, and other surface finish processes. The media are available in a wide range of types, hardness, grit and mesh sizes, and abrasiveness. What abrasive media to use for your sandblasting project?

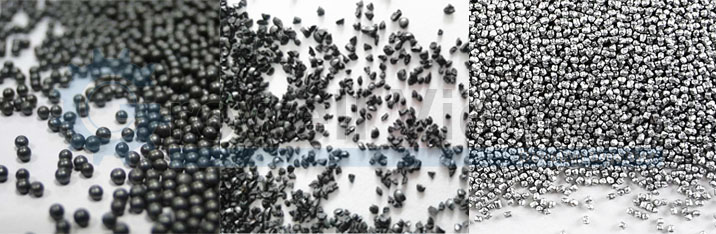

Steel Shot

Steel shot is used in the majority of the wheel blast applications and creates a dimpled, peened surface. Only the shot’s skin suffers from the impact and very thin flakes will progressively part from the shot, which itself stays round throughout its life cycle. Our steel shot is very durable with high resistance to impact fatigue, giving it an effective and quick cleaning rate.

Our high carbon steel shot is used in various applications like; desanding, descaling, cleaning, shot peening etc

Steel Grit

Steel grit produces an etched or angular surface profile and is well suited for cleaning, descaling, etching and desanding applications. Growell steel grit has a long service life and is used in both wheel blast machines and blast rooms.

Glass beads

Glass beads are a reusable abrasive media and are mainly used in blast rooms and blast cabinets. Glass beads contain no free iron to cause corrosion on non-ferrous surfaces, therefor glass beads are very suitable to use on all types of metals. Since it doesn’t create an anchor profile, it is mainly used to clean a substrate without roughening it or to polish the surface.

Brown aluminum oxide

Brown fused Alumina is mainly used as a recyclable abrasive media in blast cabinets and blast rooms. Because of its low iron content, alumina is often used in blasting operations where iron contamination on the non-ferrous metal substrate is not allowed. Aluminum oxide is a very hard and sharp abrasive that cleans rapidly. It leaves an anchor profile prior to coating and is suitable for removal of scale, rust and old coatings. Furthermore it is used for ceramic grinding wheels, refractory applications and polishing and grinding.

White aluminum oxide

White Fused Alumina is mainly used is as a recyclable abrasive media in blast cabinets and blast rooms, where high purity of the abrasive is required. Because of its low iron content, white fused alumina is often used in blasting operations where iron contamination on the non-ferrous metal substrate is not allowed. White Fused Alumina is the purest alumina and it is very hard and sharp with a fast cleaning rate.

CONTACT US RIGHT NOW TO GET MORE DETAILED INFORMATION

Reference articles:

Introducing about suction cabinet Growell VN

Introducing about blasting room

How to choose the right abrasive sand?