News

Learn more about hanger type shot blasting machine

Growell hanger type shot blasting machine is specially designed in order that components: large medium small casting, forging parts, fabricated steel products, transformers, automobile parts, alloy wheels, bicycles, gear parts, axles and tool bits, ect are hung on hook of a hoist.

Growell hanger overhead converyor types can be integrated into three kinds or any system on the market. The operation system of the machine must be decided upon, either continuous or cycle batch operation. Which transport system depends on the type of production and the blasting time.

- GHM model is mono rail hanger

- GHR model is “Y” rail hanger

- GHL model is loop hanger

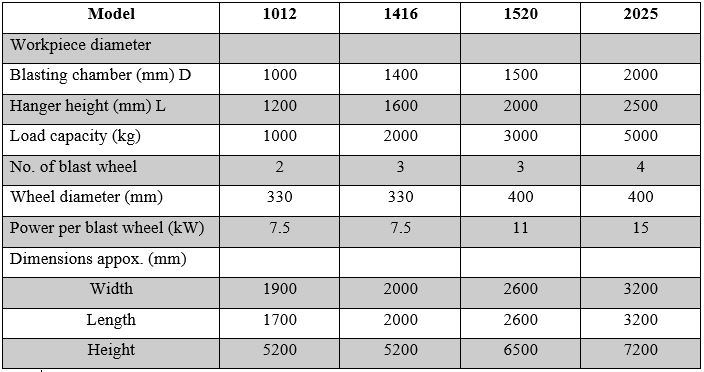

Specification of Hanger type shot blasting machine

Process description of Hanger type shot blasting machine

The hoist is controlled manually by the operator throughout the overhead conveyor outside the machine by means of ordinary push-button panel, for the component loading and unloading. Once the hoist has got to its working position, all its motors are driven by the cycle program which ovoids any misuses and control the movements of components during blasting operation. The blasting wheels are fitted on a cabine side, while the movement of the hook rotates. The surface of the workpiece is thus evenly blasted from all angles and even difficult to reach areas are optimally treated

CONTACT US NOW TO GET MORE DETAILED CONSULTANCY ON HANGER TYPE SHOT BLASTING MACHINE

Reference articles:

Introducing about suction cabinet Growell VN

Introducing about blasting room

How to choose the right abrasive sand?